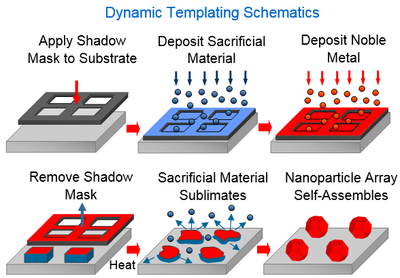

Dynamic Templating

A Lithography-Free Platform for Fabricating Periodic Arrays of Nanostructures

The deposition of a high surface energy thin film on a low surface energy substrate, followed by its subsequent dewetting and agglomeration into droplets at elevated temperatures, is the most straightforward method for obtaining substrate-based nanostructures. The imposition of a periodicity onto the dewetting process using lithographically-defined film edges, periodic templates or substrate surface texture has been demonstrated. To carry out these so-called templated dewetting procedures on the nanoscale, however, requires that order be imposed by patterns having nanoscale features. Producing periodic templated structures on these length-scales over large areas while preserving long range order becomes technically challenging and cost-prohibitive, negating the main advantage of using the templated dewetting route. We have, however, devised a directed assembly route, referred to as dynamic templating, which enhances the agglomeration process over that observed for conventional dewetting techniques. It involves the deposition of a sacrificial Sb layer through a shadow mask followed by a thin metal layer of Au. When heated, the Sb preferentially sublimates from the sides of the pedestal causing the areal dimensions of the pedestal, on which Au is agglomerating, to rapidly shrink. This leads to a forced migration of Au to the center of each pedestal, where the rate and areal extent over which the agglomeration occurs exceeds by orders of magnitude that of a Au pedestal deposited directly on the substrate surface. At the end of the process, the Sb has completely sublimed leaving behind a periodic array of substrate-immobilized nanostructures. The discovery enables the assembly of sub-micrometer and nanostructured arrays using shadow masks with easily manufactured micrometer-scale features. The technique is inexpensive, straightforward, requires only a sputter coater and tube furnace, can be carried out in a mere 3 hr and has been demonstrated for 8 different metals/alloys. Once formed, the arrays can act as templates for other assembly process yielding more sophisticated nanostructures.

Schematics showing Au template formation using dynamic templating.

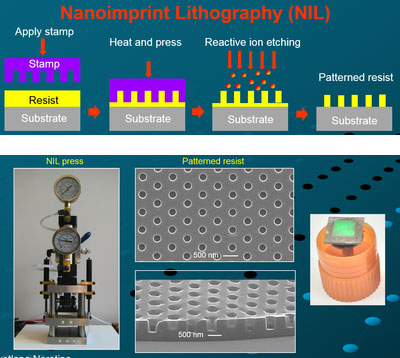

Combining Nanoimprint Lithography and Dynamic Templating

In the dynamic templating process the arrays were defined using shadow masks with 0.9 µm diameter openings and a pitch of 1.6 µm deposited over a 2 mm diameter. While such arrays are useful in demonstrating syntheses they are unsatisfactory from the standpoint of fabricating devices as both the nanostructure areal density and surface coverage is low. The goal is to integrate nanoimprint lithography into the seed fabrication process in a manner which yields higher density arrays over larger areas. The nanoimprint lithography (NIL) system has been designed, built, and validated.

A photograph of the instrument, an SEM image of a periodic array of 300 nm holes and an optical photograph of the diffraction pattern resulting from arrayed structures imprinted on a 1 cm × 1 cm sapphire substrate.

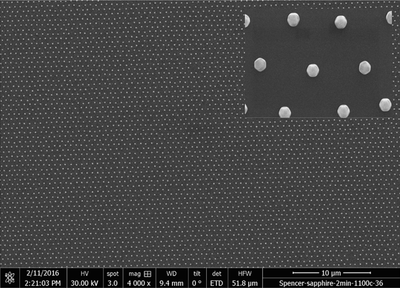

SEM image of a periodic array of Au nanostructures formed by combining dynamic templating and nanoimprint lithography.